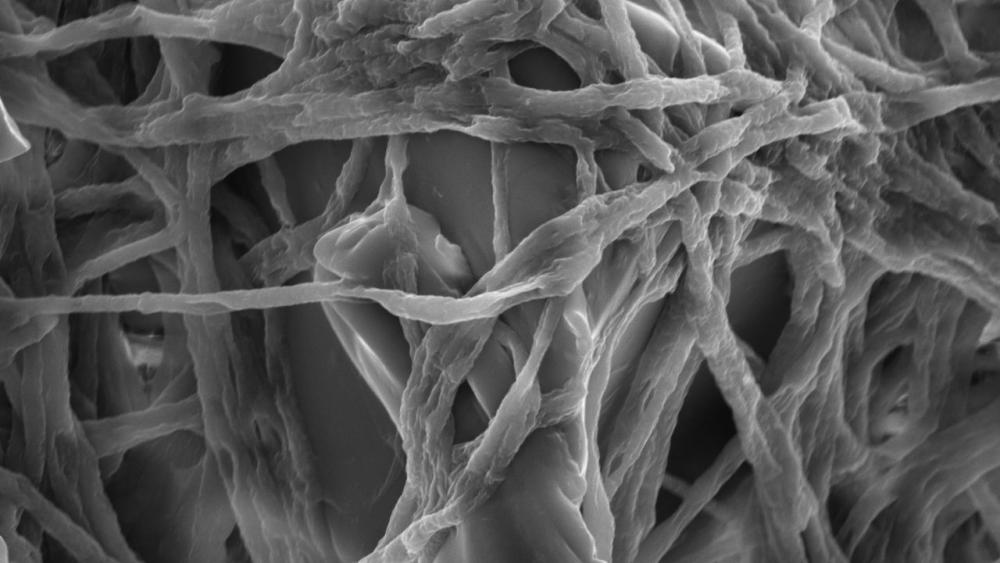

Fusarium mycelia colonise a plastic particle, eElectron microscope image. | Image: Sabreen Samuel Ibrahim Dawoud

Plastics made from polymers can persist in the environment for decades because they are not degraded, or are broken down very slowly, by bacteria in soil and water. As a result, research is underway around the world to find practical and sustainable ways to treat plastic and rubber waste. The research team has now selected 18 strains of fungi and tested their ability to break down polyurethane, polyethylene and tyre rubber. These are some of the most common plastics found in the environment. The results show that strains of Fusarium, Penicillium, Botryotinia and Trichoderma have a high potential to degrade plastics.

Fungi well adapted to the ‘plastisphere’

In recent years, researchers have shown that there are microfungi that can break down even complex polymers, making them suitable for bioremediation.

But why are fungi such good plastic recyclers? "Fungi produce enzymes that can break down chemical compounds made up of many macromolecules, such as plastic. In addition, they are well adapted to life in the plastic sphere with their invasive growth forms and their ability to form biofilms and interact with existing biofilms", said IGB researcher Professor Hans-Peter Grossart, who led the study.

Analyses using a scanning electron microscope showed the team that the cell walls of some fungi deform when they colonise the plastics. These are probably structural adaptations of the mycelia that enable them to colonise, for example, water-repellent polyurethane“, said Sabreen Samuel Ibrahim Dawoud, PhD student at IGB and first author of the study.

FT-IR spectroscopy to analyse changes in the microstructure of the fungi and DOC analysis to determine their metabolic activity provided evidence that the initial enzymatic activity of the fungi leads to the formation of intermediates that serve as a source of carbon and energy for the fungi by increasing the concentration of soluble organic carbon available for fungal growth. In this way, the fungi are constantly creating new food for themselves through degradation", said Sabreen Dawoud.

No pre-treatment with UV light, ozonation or other chemical or thermal processes required

The study also showed that fungi can degrade polymers without any pre-treatment of the plastics and without the addition of sugars as an energy source.

To initiate microbial degradation of plastic polymers, many studies have first used UV light, ozonation, chemical oxidants or thermal pretreatments to effectively oxidise the plastic polymers and generate reactive functional groups before inoculating the polymer with fungi. These treatments were not used in this study and do not appear to be essential for fungal activity. However, it has not been investigated whether such treatments would have changed the dynamics of the degradation process.

And these are the successful plastic eaters

Among the selected strains, strains of Fusarium, Penicillium, Botryotinia and Trichoderma showed a particularly high potential for degrading polyethylene, polyurethane and tyre rubber. Some of the terrestrial occurences of these fungi are not yet very popular with humans: Fusarium, for example, is known in agriculture as a harmful fungus for cereals and maize. Botryotinia can also cause various plant diseases. Trichoderma species are filamentous fungi that live worldwide in the soil, in plants, in decaying plant remains or even in wood. They are important decomposers and interact with plants, other microorganisms and the soil. Species of the genus Penicillium, on the other hand, play an important role in the production of penicillin and foods such as mouldy cheese.

The researchers also tested whether certain types of fungi can only break down certain types of plastic or rubber and which plastic is best decomposed by fungi. The result: polyurethane proved to be the most degradable of all the plastics tested. „The knowledge of more efficient strains of fungi, especially for the biodegradation of polyurethane, contributes to the development of large-scale recycling concepts for plastic waste“, concluded Hans-Peter Grossart.

******

Methodology

The study describes the procedure for sampling and identification of the 18 fungal strains from the water bodies of lakes Stechlin and Mirow in northeastern Germany and classify them using the ITS, SSU and LSU molecular data. These strains were examined for their cellulo-, lignino-, and chitinolytic activity and their ability to degrade various plastics, including polyethylene, polyurethane, rubber particles, and low-density polyethylene. Degradation assays were conducted on both agar and liquid media, with optical evaluations to observe plastic degradation and respiratory assays to measure O2 consumption and CO2 production. Fresh weight and dissolved organic carbon (DOC) were measured post-incubation, and fungal mycelia were analyzed using scanning electron microscopy (SEM) and Fourier Transform Infrared (FT-IR) spectroscopy. Regarding the data analysis, R software was used; the ANOVA, Dunn test, and linear regression were applied to compare the results and determine the correlations between them.

Excursus

- PU is one of the most widely used environmentally harmful polymers. It is used in many industries and is particularly suitable for long-term applications such as foams, elastomers for sportswear or medical devices, coatings and sealants. PU is therefore designed for harsh environmental conditions.

- PE accounts for about one third of total plastics demand in Europe, partly due to its extensive use in packaging.

- Microplastics from tyres contribute to the largest sources of microplastic pollution, including tyre abrasion particles, recycled tyre crumbs and residues from tyre repair.